Okay, 3D printing race cars is, like, my new obsession. I’m sprawled on my couch in this tiny Detroit apartment, the radiator clanking like it’s possessed, and I’m still buzzing from the first time I saw a 3D printer churn out a racecar part. It was last summer in this sketchy Ypsilanti garage, and I totally ate it—knocked over a pile of tools while staring at a 3D-printed suspension arm like it was alien tech. The mechanic, Ray, just chuckled and tossed me a rag to wipe the grease off my hands. That’s when I got it: additive manufacturing race cars isn’t just hype—it’s legit changing the game.

Traditional racecar parts? Total dinosaurs. Heavy, slow to make, and boring. But 3D printing race cars? It’s like sci-fi come to life. I held this 3D-printed bracket once; it was so light I thought it was a prop, but it was strong enough for a car ripping around a track. That said, it’s not all smooth sailing. Ray told me about a team that botched a 3D-printed wing with cheap filament—it cracked mid-race. I cringed so hard, like I was the one who screwed it up.

Why 3D Printing Race Cars Rocks My World

Lighter Parts, Faster Vibes

Building faster racecars is all about cutting weight, right? Every ounce counts when you’re hauling ass at 200 mph. I was at this scrappy race in Michigan last month, nursing a lukewarm energy drink (gross, my bad), and I overheard some engineers raving about how 3D-printed car bits slashed their car’s weight by, like, 12%. That’s insane! I saw on Motorsport.com that teams are using additive manufacturing for stuff like air ducts and brackets that are stupid light but tough as nails. I tried doodling one of those designs on a napkin once—it looked like my dog chewed it up.

Custom Parts That Make Me Lose It

Also, 3D printing in racing lets you get nuts with designs. You can make parts that fit a car or driver like they were born for it. I was snooping in a garage (okay, maybe I wasn’t supposed to be there), and I saw this 3D-printed nose cone that was straight-up art—aerodynamic perfection. It’s not just about looking cool, though it totally did. It’s about speed. 3DPrint.com says teams can whip up new designs in days, not months. I tried messing with a 3D printer once, and, uh, I ended up with a plastic blob and a buddy who still teases me about it.

My Epic Fails with 3D Printing Race Cars

I’m no engineer, just a car nerd who’s way too into lightweight racecar designs. Last year, I tried to “help” a friend print a custom racecar bracket. Total disaster. I didn’t know you had to dial in the printer settings for high-strength stuff, so we got a part that looked dope but snapped like a twig. I was standing there, face burning, grease smudged on my jeans, while my buddy just laughed. Lesson learned: 3D printing race cars isn’t a game you just jump into. You have to know your stuff.

Here’s what I’ve picked up from my dumb mistakes:

- Material’s Gotta Be Right: Use tough stuff like carbon fiber composites or PEEK for parts that take a beating. Engineering.com says PEEK is the real deal for durability.

- Test Everything: Don’t just print and cross your fingers. Stress-test the crap out of it. I saw a team tank a race because they skipped this—major oof.

- Start Small, Man: Don’t try printing a whole chassis like I stupidly suggested once. Stick to small stuff like ducts or mounts first.

The Messy Truth About 3D Printing in Racing

Alright, let’s get real—3D printing race cars isn’t all high-fives and trophies. Those printers cost more than my rent, and the materials? Don’t even. I was talking to a mechanic who said his team blew thousands figuring out additive manufacturing race cars. And the learning curve? Steeper than a racetrack turn. I saw a post on Reddit’s r/motorsport where some dude ranted about a 3D-printed part failing mid-race. I’ve been there—not racing, but I did ruin a print job once and got filament, like, all over my shirt. Ray’s probably still cackling about it.

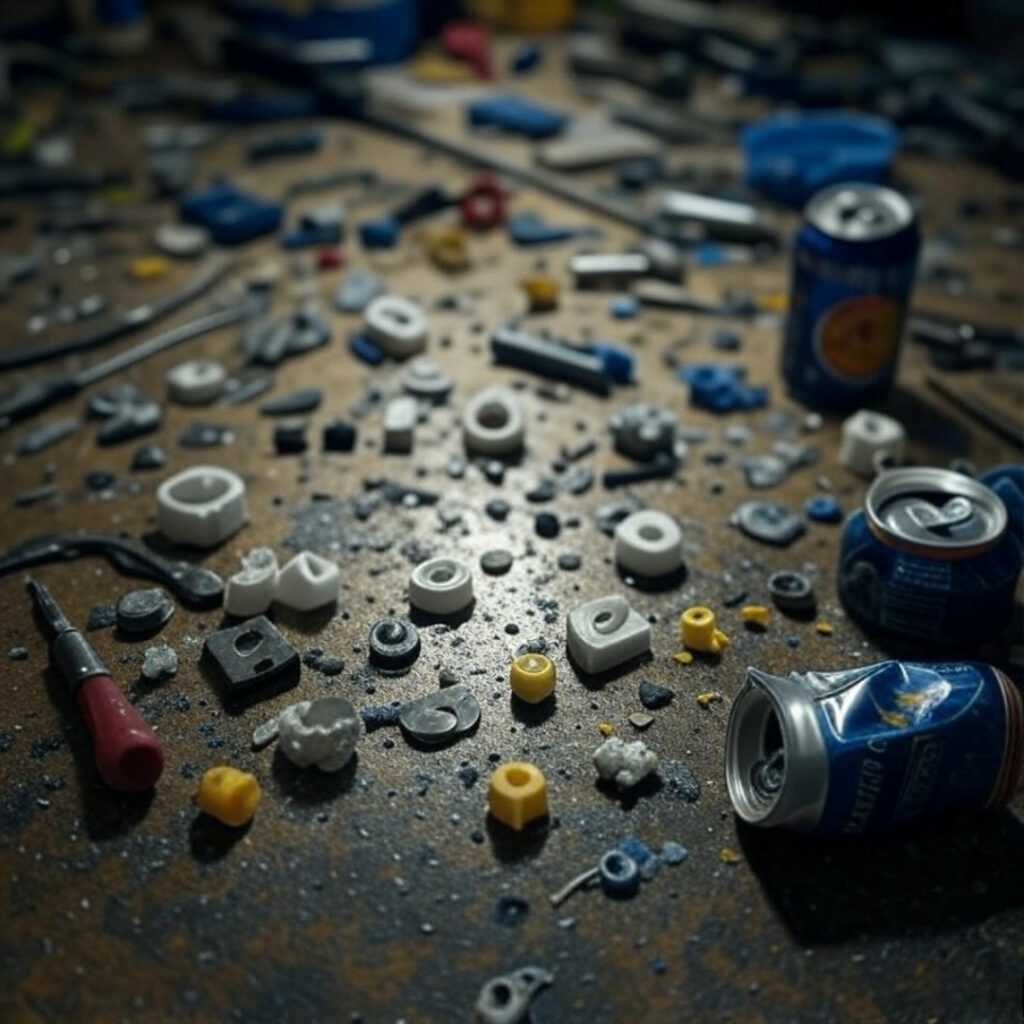

Still, the potential’s got me hyped. I’m sitting here in my chilly Detroit apartment, the radiator groaning like it’s mad at me, and I’m thinking 3D printing race cars could make racing less elitist. Small teams could prototype without selling their souls. I’m all in, even if I’m still tripping over my own feet learning this stuff.

Wrapping Up My 3D Printing Race Cars Rant

So, yeah, 3D printing race cars is freaking awesome, but it’s a hot mess too. I’m just a dude in Detroit, surrounded by empty energy drink cans and the faint whiff of motor oil on my jacket, trying to wrap my head around this tech. It’s lighter parts, faster builds, and designs that make me geek out. But it’s also screwing up and learning the hard way—I’ve got stories, man. If you’re into building faster racecars with 3D printing, jump in, but maybe don’t knock over a toolbox like I did. Got your own 3D printing wins or epic fails? Drop ‘em in the comments—I’m all ears.